Automatic Scanning of Objects of All Sizes and Geometric Complexity

Autonomous, High-Quality 3D Scans without Manual Postprocessing

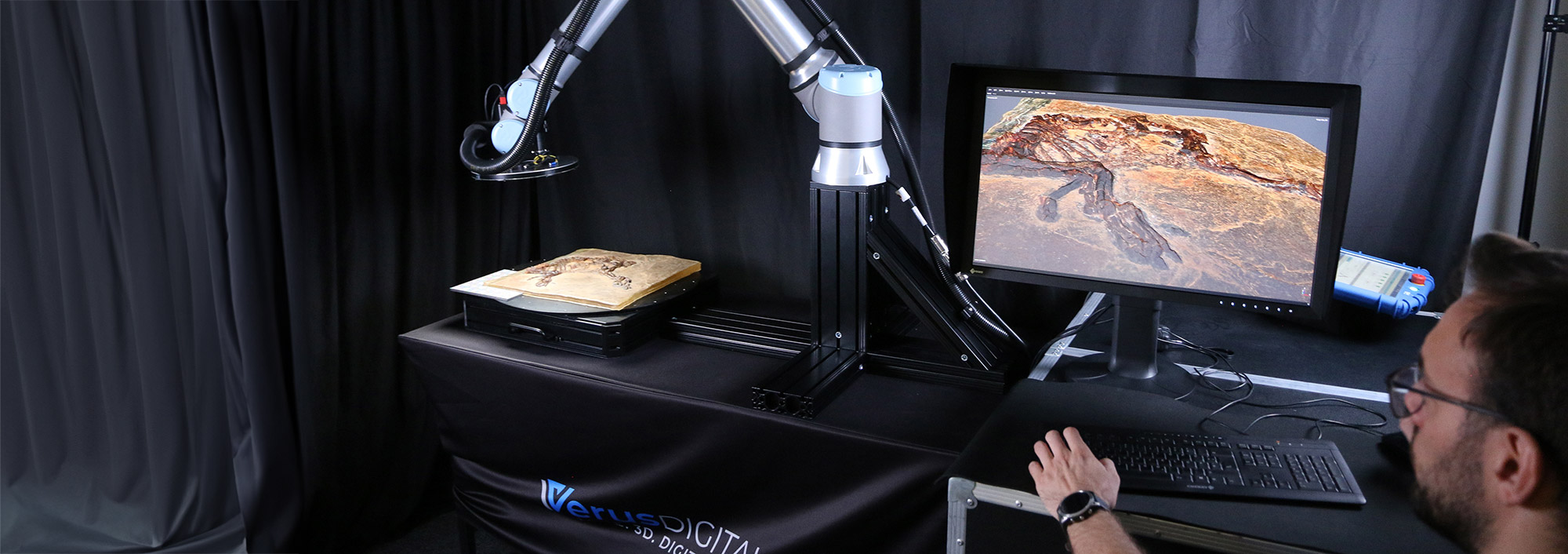

From prehistoric horses to dismantling nuclear power plants: Fraunhofer IGD has developed the first autonomous 3D scanning robot that delivers precise, color accurate scans in repeatable, high quality. The 3D robot makes it possible to digitize cultural heritage assets, such as the fossils of a prehistoric horse found at the Messel Fossil Site, and transform them into a 3D model. There are numerous other applications for the robot. These include developing precise systems for dismantling nuclear power plants and digitizing components in the automotive industry when no CAD models are available. The technology enables 3D models to be prepared without the need for postprocessing. It is already used in cultural heritage, industry, forensics, and medicine.

(Darmstadt, Germany) When it comes to digitizing surfaces, there are many challenges: Metals are shiny and reflect light. Complex, intricate details frequently make scanning difficult in the case of gemstones. The Fraunhofer Institute for Computer Graphics Research (IGD) has developed a solution that enables digital 3D scanning of objects regardless of size and geometric complexity.

The developments started with the 3D digitization of cultural heritage assets. The Fraunhofer spin-off Verus Digital GmbH offers a 3D scanning robot and 3D digitization services for museums and archives. Fraunhofer IGD is now transferring its 3D digitization expertise to other sectors and industrial applications. Not only can any surface be digitally scanned, but the resulting 3D models can also be used for specific machining processes such as autonomous robot-assisted deburring, decoating, painting, and printing.

Video on the 3D scanning of the prehistoric horse

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyPrecision for Dismantling Nuclear Power Plants

One example of this technology transfer is developing a high-precision, autonomous robot-assisted decoating system for dismantling nuclear power plants. Pedro Santos, Head of the Competence Center for Cultural Heritage Digitization at Fraunhofer IGD, explains: “In nuclear power plant dismantling, the challenges are enormous. Many pipes and steel beams have a so-called decontamination coating that aggregates radioactive activity. During the dismantling process, the pipes are cut out and divided, so CAD models no longer describe their geometry. However, the activated coating must be safely removed. This was previously done by chemical baths or manual decoating using ultra-high-pressure water jetting, which required continuous monitoring of each employee’s radiation dosage. The work shifts were, therefore, shorter, and more staff was needed.”

“Because we can scan individual geometries autonomously and completely using our technology, we have automated this process.” According to Santos, a robot can now scan any assembly in 3D and subsequently decoat it autonomously and in repeatable quality, without the presence of a worker in an environment that is loud, potentially dangerous, and wet due to spray mist. Fraunhofer IGD’s system has been deployed in Block A of the Biblis nuclear power plant for the past seven months.

Technology Transfer to Evidence Digitization and Forensics

Fraunhofer IGD's systems are also used in evidence digitization and forensics, in addition to their applications in nuclear power plant dismantling. Evidence rooms are digitized using 3D scanning robots as part of a project with the Hesse police. This gives officers access to high-resolution 3D models of evidence seized at crime scenes anytime and from anywhere, eliminating the need to transport items of interest from the evidence room to the respective department. It also enables departments at different locations to access the same evidence simultaneously. In a project with the Institute of Forensic Medicine at the University of Zurich, CT scans performed during autopsies are now combined with 3D surface scans to identify characteristic features of causes of death based on a correlation of the two technologies. Santos explains: “This technique makes it possible to visualize skin discoloration on a wound with the penetration depth of an instrument of crime in a single 3D model, for example.”

Technology Transfer to the Automotive Industry

The technology is also beneficial in the automotive sector. It can be used, for example, to keep vintage and classic cars in roadworthy condition for longer. For many classic cars, original equipment manufacturer (OEM) parts become unavailable at some point. When collectors want a historically accurate replica, they sometimes look for old molds to reproduce the replacement part true to the original using old methods. This is highly costly.

A more cost-effective solution is digitizing a damaged OEM part in 3D using Fraunhofer technologies, repairing it virtually, and reproducing it in a 3D printout. Depending on its use in the vehicle, the part must be approved for safety-relevant assemblies or undergo acceptance testing by TÜV. Additional industrial applications in the automotive sector include finishing certain assemblies: A saddlemaker may cover a manufacturer’s dashboard with custom leather, for example. In such cases, an autonomous 3D digitization of the assembly can be the basis for a custom pattern.

Developing Standards for 3D Color Calibration

Fraunhofer IGD is expanding its autonomous 3D scanning robots to create more comprehensive and precise digital models. This includes multispectral surface mapping and developing standards for 3D color calibration to ensure comparable results in 3D worldwide, as is currently the case for 2D. “In the next decade, we will focus on combining the results of different measurement technologies, such as 3D surface scans, CT scans, terahertz, and ultrasound images of an object, into a consolidated 3D model of the same object (a digital twin) to visualize, correlate, and analyze the results of different measurement methods using AI,” says Santos.

“Digital Twin Ensures Long-Term Access to Art and Culture”

At the Eurographics Workshop on Graphics and Cultural Heritage (GCH 2024) in Darmstadt, Germany, Fraunhofer IGD will present a digital twin autonomously scanned and computed in 3D. Researchers will also show a 3D replica of the third prehistoric horse recently discovered at the Messel Fossil Pit, a UNESCO World Heritage Site. The little horse was 3D-printed using Fraunhofer technology.

“We entrusted Fraunhofer IGD, with its many years of expertise, to digitize such a rare and valuable asset using 3D scanning, and we were not disappointed. The digital twin will guarantee long-term access to art, culture, and natural treasures for a broad audience and experts worldwide,” says an enthusiastic Philipe Havlik, CEO of Welterbe Grube Messel gGmbH.

During the workshop at the Hessisches Landesmuseum in Darmstadt from September 16 to 18, 2024, researchers will present new approaches and technologies for digital knowledge transfer in cultural and natural heritage settings and discuss the use of such technologies in various applications.

Fraunhofer Institute for Computer Graphics Research IGD

Fraunhofer Institute for Computer Graphics Research IGD