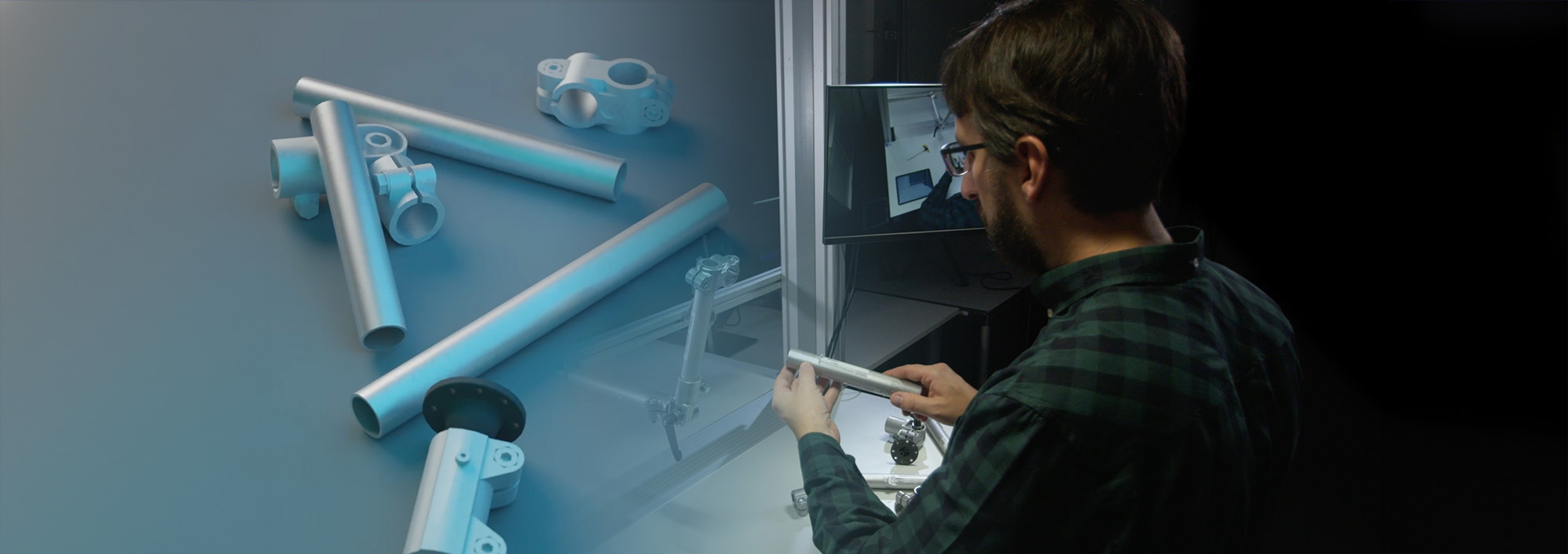

Synthetic training of AI solutions

Generation of training data made easy

Systems based on artificial intelligence (AI) require training data – this is an essential prerequisite for their success. But users in the manufacturing industry face challenges for quickly obtaining sufficient quantities of it. Fraunhofer IGD is therefore working with synthetically generated training data. This approach is letting its researchers meet the prerequisites for machine learning and automated inspection of components faster, more simply, and more cost-effectively.

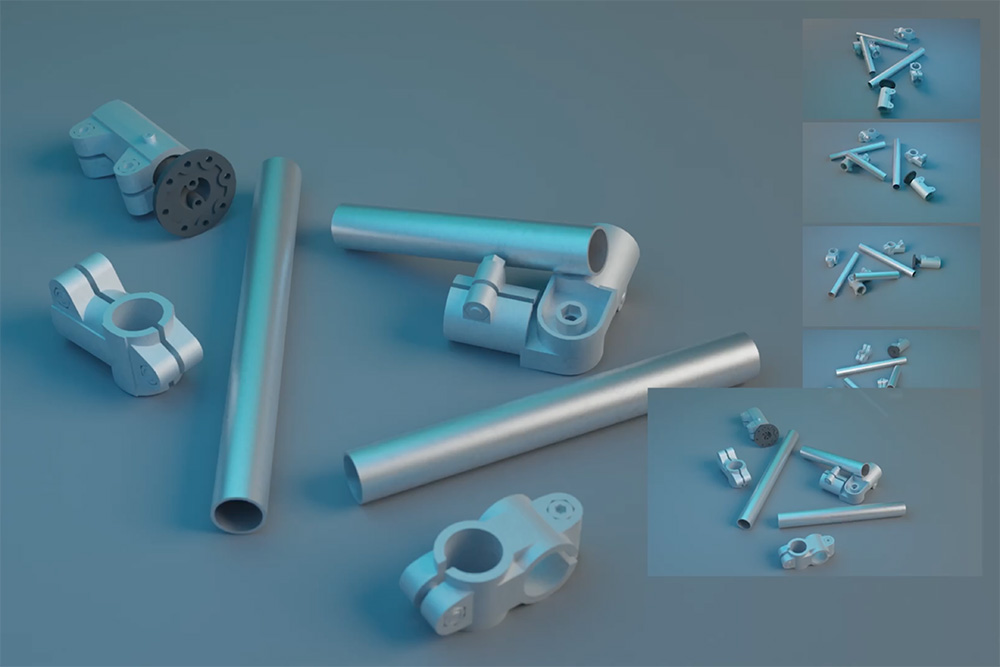

(Darmstadt, Germany) Users often require hundreds or even thousands of photographs of an object in order to train an AI. This poses challenges in an actual industrial context: the component has to be produced first, and training data can’t be derived until a late stage of the manufacturing process. Especially with prototypes and small lots, this isn’t practicable. It would also be too time-consuming and costly to manually identify and classify all of the depicted elements. Scientists at the Fraunhofer Institute for Computer Graphics Research IGD therefore set out to synthetically generate training data.

Automated inspection of parts

“This is a major step forward for users,” says Prof. André Stork, Head of the Automative Competence Center at Fraunhofer IGD. “They can start training neuronal networks even before an object actually physically exists.” The technology takes advantage of preexisting native CAD data to generate images as viewed from different perspectives under a variety of lighting conditions and with a wide range of textures and/or material properties.

Fraunhofer IGD primarily develops solutions of this type to support companies of the manufacturing industry: automotive and aircraft builders, for example, as well as parts suppliers and machine and plant builders, can all benefit from automated component inspections. The AI captures actual installed parts and compares them with the correctly executed work that it has learned to look for. “This mainly supports quality control,” says Stork. “Users can also make up for a lack of trained workers by having an AI perform some of the tasks involved.”

At the 36th Control trade show in Stuttgart, Germany, which will take place from April 23 to 26 of this year, Fraunhofer IGD will present an AR-supported assembly table that has been trained on synthetically generated data.

Fraunhofer Institute for Computer Graphics Research IGD

Fraunhofer Institute for Computer Graphics Research IGD